New challenges require new solutions – 3D-MID for automotive applications

In the history of mankind there has been hardly any other technology that is causing such emotion and enthusiasm as the automobile. The car offers personal mobility and freedom that characterizes our way of life. While we get used to this freedom and we don’t want to give it up, yet we must deal with the negative side effects and keep the costs of this freedom as low as possible. This is a major challenge for car manufacturers.

Car manufacturer have taken on this challenge for a long time and have overcome a number of tasks. Significant reduction in CO2 emission was achieved in the last decade and countless safety and comfort options have been added. Plastics have replaced a large numbers of metal parts resulting in weight reduction, and electronics have found their way into automobiles to manage nearly everything in a car.

Driving assistance systems, for example, manage the distance to the vehicle in front, monitor the “blind spot”, warn the driver of unintentional lane departure, identify critical situations and help the driver to cope with them. These are just a few examples of the safety and convenience function of the modern automobile.

New challenges require new solutions

In order to work properly and safely these systems need to communicate with each other, and their integration requires space that shouldn’t come at the expense of user comfort. The diversity and complexity of these systems increases their fragility. This requires increased reliability and additional efforts to control such systems, and it is essential that the costs incurred must remain reasonable.

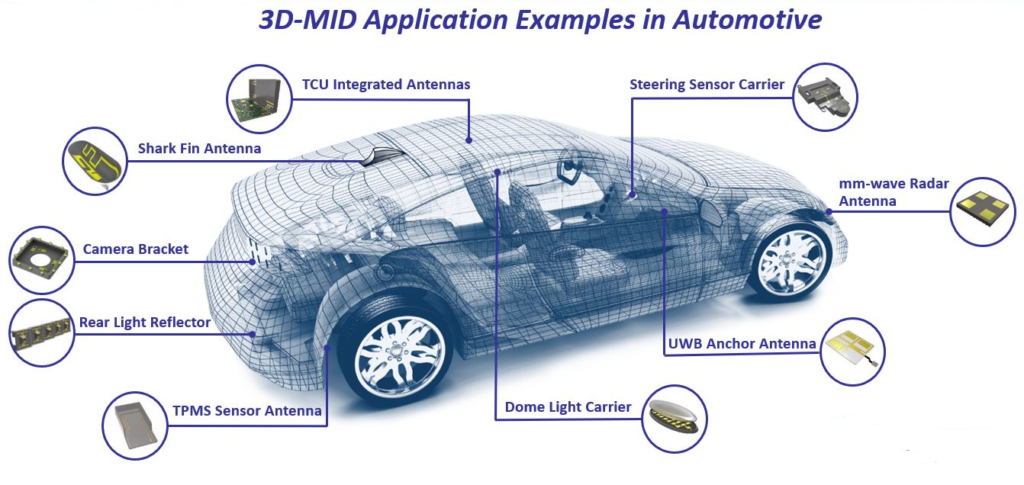

Reliable communication, space reduction and managing complexity at reasonable costs are significant challenges which must be taken into account while designing new products. In this regard 3D-MID technology can be of great help.

The advantages of 3D-MID technology

- Optimal use of space thanks to their three-dimensional shape

- Integration of mechanical and electronic functions by combining plastic and electronics

- Reduction in the number of components and process steps by integrating several components into a single module

In other words, 3D-MID technology stands for miniaturization and system simplification. The technology already has a foothold in various industrial fields such as Medical, Electronics and Telecommunications. In recent years several hundreds of millions of 3D antennas for mobile phones have been manufactured. In the automotive field, 3D-MID is used for sensors, switches, antennas and more and more applications are being added.

Kind regards and best wishes

Nouhad